NS net Peer Review of Keihin Product Operations, Toshiba Corporation, was conducted over the three-day period starting July 21st. A summary of the review is shown below NS net Peer Review of Keihin Product Operations, Toshiba Corporation, was conducted over the three-day period starting July 21st. A summary of the review is shown below

|

1. Reviewed Establishment (location) |

|

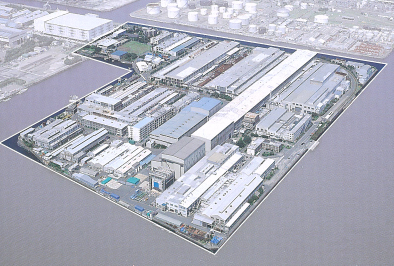

Keihin Product Operations, Industrial and Power Systems & Services Company, located in Tsurumi-ku, Yokohama, Kanagawa Pref Keihin Product Operations, Industrial and Power Systems & Services Company, located in Tsurumi-ku, Yokohama, Kanagawa Pref |

2. Overview of the establishment and targets of review |

|

Since its foundation in 1875, Toshiba Corporation has created many excellent technologies and high-quality products and services and promoted business management geared to respond promptly to a constantly evolving business environment.The company started research and development in the nuclear energy field in 1955 and then undertook design, production and construction of a boiling water reactor (BWR) following its introduction of technology from General Electric Company of the US. The company has now constructed 21 units so far, across the country. Two more units are currently under construction. Two of the 21 units already built and one of the two units under construction are advanced boiling water reactors (ABWR). The ABWR was developed on the basis of Toshiba's construction experiences and research advances and integrates the world's best BWR demonstration technologies for improving safety and reliability, operability and usability and cost efficiency, and for reducing radiation exposure and generation of radioactive waste. Since its foundation in 1875, Toshiba Corporation has created many excellent technologies and high-quality products and services and promoted business management geared to respond promptly to a constantly evolving business environment.The company started research and development in the nuclear energy field in 1955 and then undertook design, production and construction of a boiling water reactor (BWR) following its introduction of technology from General Electric Company of the US. The company has now constructed 21 units so far, across the country. Two more units are currently under construction. Two of the 21 units already built and one of the two units under construction are advanced boiling water reactors (ABWR). The ABWR was developed on the basis of Toshiba's construction experiences and research advances and integrates the world's best BWR demonstration technologies for improving safety and reliability, operability and usability and cost efficiency, and for reducing radiation exposure and generation of radioactive waste.

The Nuclear Energy Equipment Manufacuturing Department (NEEMD), Nuclear Division, Keihin Product Operations, designs and produces boiling water reactors under a consistent organization system while also developing and fabricating components and equipment for fast breeder reactors, high temperature gas-cooled reactors and reprocessing facilities. The Nuclear Energy Equipment Manufacuturing Department (NEEMD), Nuclear Division, Keihin Product Operations, designs and produces boiling water reactors under a consistent organization system while also developing and fabricating components and equipment for fast breeder reactors, high temperature gas-cooled reactors and reprocessing facilities. |

3. Members of the review team and the method of review

Group A

|

: |

Shikoku Electric Power Company, Japan Nuclear Fuel Limited,,

(Fields of review: organization and operation, education and training and handling of important issues) |

| Group B |

: |

Japan Nuclear Cycle Development Institute, NS net

(Fields of review: design, manufacture and handling of major issues) |

| Method of review |

: |

Field observation, interviews with persons involved in and examination of documents in the above areas |

|

|

Keihin Product Operations,

Keihin Product Operations, |

Document examination

Document examination |

|

|

4. Results of this review

|

(1) Main Conclusions (1) Main Conclusions |

|

• |

In summing up this review of Keihin Product Operations, Toshiba Corporation, we have not found any item in the nuclear safety field that would lead to a serious accident unless immediate remedies were taken. |

|

• |

Under the current changing circumstances surrounding the nuclear power business, Keihin Product Operations is developing "Keihin's Vitality Plan for Product Creation" on an organization-wide scale. Operations carry out "MI" (Management Innovation) as part of management innovation activities and "SGP" (Small Group Projects) as part of its small group activities. These measures have resulted in development and dissemination of skills and technologies, allowed employee to enhance their capabilities, and produced improved working manuals and increased of communications. Top management supports these activities by setting an example to be followed throughout the organization. |

|

• |

In designing and manufacturing nuclear reactor components and equipment, Operations has set up information system groups for design, production technologies, tests and inspections and production progress that fully utilize IT techniques, such as a comprehensive production system. Giving employees direct utilization of these information system groups contributes to correct and immediate operations. |

|

• |

In the future, it is desirable that Keihin Product Operations should reinforce efforts to achieve an enhanced safety culture, and not accept things as they are. |

(2) Good Practices and Suggestions for Improvement (2) Good Practices and Suggestions for Improvement |

| |

This Peer Review selects good practices that should be widely introduced to other NSnet members and within the nuclear power industry. It also makes numerous suggestions for improvement that would be useful in improving the safety culture at Keihin Product Operations, and these provided the focus of the Peer Review. This Peer Review selects good practices that should be widely introduced to other NSnet members and within the nuclear power industry. It also makes numerous suggestions for improvement that would be useful in improving the safety culture at Keihin Product Operations, and these provided the focus of the Peer Review.

A brief look at Good Practices*¹ and Suggestions for improvement*² follows below. A brief look at Good Practices*¹ and Suggestions for improvement*² follows below. |

|

a. Good Practices a. Good Practices

|

Fields of review |

Summary of good practices |

Organization and Administration |

| • |

Ensured proper personnel through flexible staffing |

| • |

Direct communication with the general manager of Keihin Product Operations. |

| • |

Support for education related to moral improvement through "e-learning education" |

|

Education and Training |

| • |

Announcement of excellent technicians on field bulletin boards |

| • |

Implementation of "Keihin's Vitality Plan for Product Creation" |

|

Design and Manufacturing |

| • |

Enhanced communication through a liaison meeting for all design engineers in NEEMD |

| • |

Enhanced communication through MI (Management Innovation) activities |

| • |

Development of multi-skilled workers in the manufacturing section |

| • |

Optimization of production process control through use of "computerized product flow system" |

|

Handling of important issues |

| • |

Ensured quality through quality patrol |

|

|

|

b. Suggestions for Improvement b. Suggestions for Improvement

|

Fields of review |

Summary of Suggestions for Improvement |

Design and Manufacturing |

| • |

Stipulate that a list of expert engineers is used to select specialists joining "design review" and "DR meeting." |

|

Handling of important issues |

| • |

Further utilization of "Hiyari-Hatto (near accidents)" cases. |

|

|

|

|

.

|

*1 : Good Practices

Information on good practices incorporating appropriate, effective, and unique methods into activities to ensure safety should be widely distributed to the members of the NSnet and the nuclear industry. Information on good practices incorporating appropriate, effective, and unique methods into activities to ensure safety should be widely distributed to the members of the NSnet and the nuclear industry.

*2 : Suggestions for Improvement

After comparing the practices of Keihin Product Operations with the best in the nuclear industry, suggestions on how to improve and enhance safety activities should be implemented to achieve the highest level of nuclear safety. After comparing the practices of Keihin Product Operations with the best in the nuclear industry, suggestions on how to improve and enhance safety activities should be implemented to achieve the highest level of nuclear safety.

Even if current activities are equal to or higher than general standards in the nuclear industry, suggestion should be taken up in case there is still room for improvement. Even if current activities are equal to or higher than general standards in the nuclear industry, suggestion should be taken up in case there is still room for improvement.

.

|

|