|

Tokyo Electric Power Company has completed the in-core inspections of all reactor units today (February19), when a Phase 3 inspection on Unit 3 was concluded.This Report #13 explains the implementation details and outcome of in-core inspections, as well as the results of other inspections and the status of non-conformity management.

The Report also provides an overview of the “International Symposium on Seismic Safety of Nuclear Power Plants and Lessons learned from the Niigataken Chuetsu-oki Earthquake”, scheduled for next week.

|

| |

|

|

| 1. |

Status of main inspections and restoration work |

| (1) |

In-core inspections |

| |

The attachment summarizes a series of work implemented from reactor opening to fuel transfer and in-core inspection (Phases 1 to 3) and their respective current status.

Several non-conformities have been identified, as listed below, in the course of the applicable work, but none of them represented an event that could seriously impact the plants’ performance or safety.No other abnormalities such as “damage, deformation and dislodgment” have been identified.

|

| |

|

| |

a. |

Unit 1:Deformation of the steam-water separator at the legs for temporary placement |

| |

○ |

On September 27 last year, an inspection on the steam-water separator, which was placed in a temporary storage pool at the time, identified deformation at its legs for temporary placement (4 out of 4 legs) and guide pins for determining the device’s position during installation inside the reactor (2 out of 2 pins). |

| |

○ |

The temporary placement legs and guide pins are auxiliary fittings of the steam-water separator, and do not affect its functions or structure.The deformation of the legs scratches the floor of the temporary storage pool, but no water leakage has been reported from this location. |

| |

|

| |

b. |

Unit 5:Shutdown of the refueling machine’s automatic operation during fuel transfer due to abnormal loading |

| |

○ |

On November 11 last year, during fuel transfer, an alarm was sounded, indicating that the refueling machine is becoming overloaded, and shutting down the machine’s automatic operation.An underwater camera was subsequently used to inspect the outside of the applicable fuel assemblies, and found that they had become dislodged from support fittings that keep the assemblies in the correct position. |

| |

○ |

The applicable fuel assemblies and their support fittings show no major deformation or other visual abnormality, and the iodine concentration of the reactor water also showed no significant change.This indicated that there was no damage to the fuel loaded in the reactor. |

| |

○ |

The dislodgment of the applicable fuel assemblies has been attributed to incorrect loading for unknown reason at the time of outage (May last year), which triggered dislodgment when the assemblies became subject to earthquake tremors or other factors. |

| |

○ |

The fuel assembly that could not be removed during the in-core inspection, was placed in the support fittings (in the correct position) on November 20, before being transferred to the spent fuel storage pool.Once the in-core inspection is completed, the distortion of the channel boxes will be measured to determine the cause of the incident in more details. |

| |

|

| |

c. |

Unit 5:Displacement of a wedge for the jet pump (No.1) |

| |

○ |

On November 29 last year, on one of 20 jet pumps, the wedge, inserted from the top to control the vibration of the inlet mixer during its operation, was found displaced. |

| |

○ |

The inlet mixer is securely affixed to the riser pipe with an upper beam, and the displacement of the applicable wedge causes no safety issues.At the time of the earthquake, Unit 5 was in the shutdown state for outage. |

| |

○ |

Subsequent inspections of the remaining 19 jet pumps did not identify any similar abnormality.TEPCO plans to look into the cause of the displacement. |

| |

|

| |

d. |

Units 6 and 7:Inability to retrieve control rods [Unrelated to the Chuetsu-oki Earthquake] |

| |

○ |

Issues with control rod removal were reported at Unit 7 for one of its control rods on October 18 last year during fuel transfer, and at Unit 6 for two of its control rods on November 23 and 25 last year during fuel transfer.In all of the cases, the control rods were successfully retrieved according to the pre-defined restoration procedure. |

| |

○ |

An inspection on the control rod drive mechanisms, control rods and reactor-side equipment identified no events (foreign matter, damage, etc.) that could be attributable to the nonconformity. |

| |

○ |

A subsequent study to identify common factors between Units 6 and 7 pointed to extended halt of water feeding for the prevention of foreign matter entry.The halt, which lasted longer than at the time of regular plant shutdown, is suspected of having increased the entry of cladding materials (rust and other metal impurities), and temporarily raised friction resistance within the control rod drive mechanisms, causing rod removal difficulty. |

| |

○ |

Even if a similar event develops in the future, it can be rectified with a scram operation, etc.Also, interference from cladding materials would not compromise the control rod drive mechanism’s rod insertion function. |

| |

|

| |

e. |

Unit 7:Detection of drain water from the reactor well liners |

| |

○ |

In regard to water identified on October 8 last year in the level gauge connected to the well liner, minor damage that could lead to leakage was found at two locations on November 7.It was subsequently confirmed that there was minor damage that could lead to leakage at a total of two locations (3mm and 2mm in length).The sections were covered with stainless steel sheets (leakage prevention covers) as temporary repair work. |

| |

○ |

An investigation into the cause of the incident found that the damage occurred in the liner’s welded section.Since the locations presented structural difficulty for welding work, the welding material may not have fully melted during welding work at the time of plant construction (for incomplete welding).Also, the use of a grinder as finishing work for welded sections removed extra weld for reinforcement, reducing the thickness of the remaining metal.It is believed that, following the Niigata Chuetsu-oki Earthquake, a slot plug struck the area near the applicable locations, causing penetration cracks. |

| |

○ |

The section cut out for the causal investigation (on the main unit of the liner) will be repaired through welding by February 26, 2008.Leakage from the reactor well will be checked when filling the well next time. |

| |

|

| (2) |

Other inspection result |

| |

An ultrasonic test was conducted from January 22 to February 13 to examine the cracks (1 coupling) identified in the previous inspection on the recirculation system piping at Unit 3.The test did not find any new damage that would classify as cracks. |

| |

|

| 2. |

Status of non-conformity management (associated with the Chuetsu-oki Earthquake) |

| |

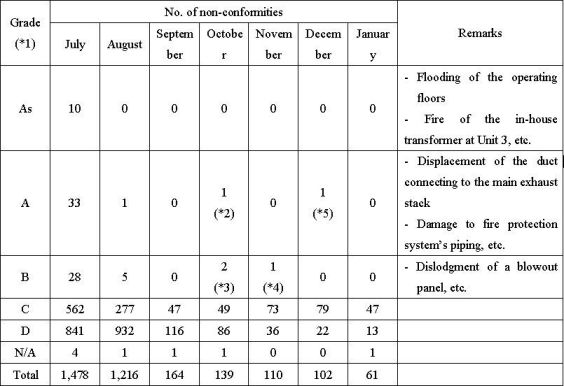

TEPCOdefines the management status of non-conformities at power stations into six grades (As – Not applicable) and regularly releases the information.The screening status of non-conformities as of the end of January is as follows.There are just under 3,300 earthquake-related non-conformities, and most of them are classified as minor events of Grade C or below. |

|

(*1)

As:Reportable event as stipulated by law or Safety Regulations (events that have a serious impact on plant performance and safety)

A :Serious non-conformity against quality assurance requirements (events that have a serious impact on outage schedule) etc.

B :Non-conformity pointed out in a government inspection (events that require enhanced operation monitoring, etc.)

C :Minor non-conformities against quality assurance requirements, etc.

D :Events within the scope of normal maintenance, etc.

N/A:Replacement of a consumable and equivalent events, etc.

(*2) Unit 7:Detection of drain water from the reactor well liners

(*3) Unit 7:Water leakage inside the reactor building (radiologically controlled area) (2 cases:See Report #11)

(*4) Unit 5:Shutdown of the refueling machine’s automatic operation during fuel transfer due to abnormal loading

(*5) Unit 5:Displacement of a wedge for the jet pump (No.1)

|

| |

|

| 3. |

Outlines of the International Symposium on Seismic Safety of Nuclear Power Plants and Lessons Learned from the Niigataken Chuetsu-oki Earthquake |

| |

The Niigata Chuetsu-oki Earthquake presented numerous challenges involved in operating nuclear power stations in an earthquke-prone country like Japan.Currently, TEPCO is undertaking inspections, restoration work and geological surveys, while the government investigates into facts on specific effects of the earthquake on the Kashiwazaki Kariwa Nuclear Power Station, and deliberates on future tasks and responses in light of the earthquake.

In the given situation, the Japan Atomic Industrial Forum (JAIF), Central Research Institute of Electric Power Industry (CRIEPI) and JANTI have banded together to organize an international symposium in the local community of the Kashiwazaki Kariwa Nuclear Power Station with focus on integrity assessment of plant equipment affected by an earthquake, influence of quake-induced ground deformation, and fire protection / prevention.The three parties believe that it is the nuclear industry’s duty to approach these matters as its own issues to address, rather than waiting for the outcome of government deliberations.The parties are committed to:

|

| |

(1) |

Amassing engineering insight from around the world to further enhance the anti-quake safety and reliability of nuclear power stations, and |

| |

(2) |

Providing and offering explanation to various information so as to help local residents and the rest of the Japanese population establish better understanding. |

| |

The symposium has attracted participation applications from local residents, local governments, national government, mass media, universities, electric power companies and manufacturers in Japan in the number that far surpasses initial projection.Over ten countries have also registered their interest in participation.This reflects the high level of expectations and interest in the symposium. |

| |

|

|

| |

<Symposium outlines> |

| |

a. |

Period: February 26 (Tue) – 27 (Wed), 2008 |

| |

b. |

Venue: “Bunka Hall” of “Kashiwazaki Sangyo Bunka Kaikan” (KashiwazakiCity, NiigataPrefecture) |

| |

c. |

Program:

|

|

|

1) |

Opening, welcome address, keynote address, special lecture |

|

|

2) |

Session 1:Integrity Evaluation of Equipment Affected by the Earthquake |

|

|

3) |

Session 2:Earthquake Induced Ground Deformation – Its Impact and Safety Significance |

|

|

4) |

Session 3:Emergency Preparedness and Fire Protection |

|

|

5) |

Concluding session, closing |

| |

|

|

| |

END |