|

Japan Nuclear Technology Institute (JANTI) established the “Structural Integrity Assessment Committee for Nuclear Components damaged by Earthquake (SANE)” (chaired by Toshiharu Nomoto, Professor Emeritus of the University of Tokyo) at the end of September 2007 to examine the structural integrity of important equipment subjected to a seismic load that exceeds the design-basis level, develop and implement appropriate measures, and share the valuable lessons learned from disasters widely with the parties concerned. The Committee consists of academic experts specializing in structural strength, inspection, earthquake resistance, and other areas, and members from electric power companies and manufacturers.

As reported in Report #17, we published an interim report in June 2008, putting together the achievements of FY2007. In this report, we will report the achievements of in FY2008, which were compiled in another interim report published in June this year, and the plan for FY2009. For details, please refer to the report posted on the JANTI homepage.

|

| |

|

| 1. |

FY2008 Activity Status |

The Committee held a total of five committee meetings at a pace of roughly one meeting every two months by the end of FY2008. The five Working Groups (WGs) set up under the Committee convened meetings more frequently for a total of 25 sessions. These, including new initiatives such as the “Visualization Task” with the aim of better explaining information about safety margins, promoted integrity assessment activities proactively.

|

| |

|

| (1) |

Scope of Assessment and Subjects for Deliberation |

| |

The following will be deliberated mainly with respect to the components, piping, and support structures forming the reactor coolant pressure boundary:

(i)Methods for assessing the integrity of components subjected to seismic load

(ii)Assessment of the integrity and safety margin of plant equipment |

| |

|

| (2) |

Outline of Committee and WGs |

| |

Since FY2008, a total of 26 expert members from universities and research institutes, including eight experts specializing in architecture and civil engineering, and about 40 full-time members from electric power companies and manufactures, have participated in this Committee. The WGs were reorganized to convene the five WGs and one task shown in the table below as appropriate to work on separate engineering issues for the continuous use of equipment.

|

| |

|

Table 1:List of Working Groups established under the Committee

| WG Name |

Main Subjects Examined by WG

|

| Structural integrity standard WG

|

Methods and standards for assessing structural integrity

|

| Inspection WG |

Methods for examining equipment’s plastic strains |

| Fatigue/Material test WG

|

Evaluation of fatigue strength of materials subjected to seismic load

|

| Building-Component Coupled analysis WG

|

Reasonable methods for evaluating reactor body foundations

|

| Pipe Vibration Evaluation WG

|

Evaluation of safety margins, e.g. piping damping coefficients, and reasonable piping design methods

|

| “Visualization” Task |

Improvement in explaining information about safety margins

|

|

| |

|

| 2. |

Achievements of FY2008 |

The initial subjects of the Committee included a main framework for integrity assessment that combines inspection with analysis, data-based evaluation of fatigue breakdown modes, methods for measuring plastic strains, and fastener member inspection methods. The results of the examinations of these subjects were used indirectly in the TEPCO Unit 7 integrity assessment report and various deliberation processes of the national government. The results of the examinations into the elastic-plastic analysis method applied to reactor pressure vessel pedestal were used in the Unit 6 seismic safety assessment report. The engineering achievements of FY2008 are outlined below.

|

| |

|

| (1) |

Examination of Methods for Inspecting Components Subjected to Seismic Load |

| |

Testing and inspecting components is an effective way of directly examining the results of seismic effects. The standards that should be followed to perform equipment inspections and the qualification and competence required of inspectors and evaluators were examined.

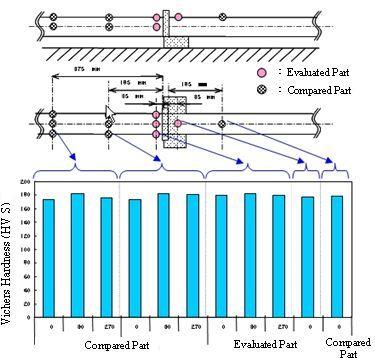

In FY2008, issues that were involved in the application of the plastic strain measuring method (Hardness method) examined the previous year to actual systems were deliberated to present countermeasures and the way to assess whether plastic strains occurred due to an earthquake. Figure 1 shows an example of a measurement of the hardness of the Unit 7 standby liquid control system pipes. If plastic strains occur due to seismic load, it is then expected that the evaluated parts will be harder (with greater maximum and minimum values). However, the differences between the values measured at the evaluated parts and the parts for comparison (compared parts) that were slightly affected by the earthquake fell within the range of measurement errors (variations). There were no occurrences of plastic strains that would affect equipment integrity.

|

| |

|

(Evaluated Parts)

|

(Results of Evaluation of Plastic Strains by Hardness Measurement) |

(Measuring Hardness) |

| Figure 1. Example of Measurement of Hardness of Standby Liquid Control System Pipes |

|

| |

|

| |

As methods for evaluating the integrity of component foundations, the torque measuring method to check fastening power and the ultrasonic inspection method to check the occurrence of cracks in anchor bolts were proposed. Figure 2 shows the overview images of the Unit 7 anchor bolts, the integrity of which was examined using these methods.

|

| |

|

|

| |

|

| (2) |

Seismic Safety Assessment of RPV Pedestal by Elastic-Plastic Analysis |

| |

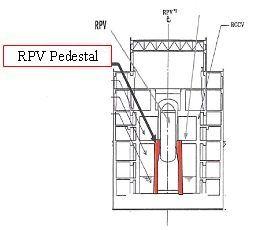

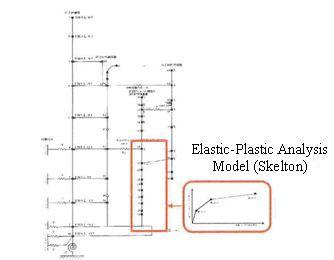

In a seismic response analysis coupling the reactor building, reactor containment vessel, RPV pedestal, and others, which is performed to evaluate seismic safety against the design-basis seismic motion Ss, coupled seismic response analysis was conventionally performed using the non-linear model for the reactor building and the linear model for the RPV pedestal. However, an elastic-plastic analysis model was developed, taking into account the structural type of the RPV pedestal (see Figure 3).

This method, including the newly developed elastic-plastic analysis model, was applied to the evaluation of the ABWR RPV pedestal against the design-basis seismic motion Ss. As a result, reasonable analysis results were obtained and seismic safety against the design-basis seismic motion Ss was confirmed.

|

| |

|

(Longitudinal View of ReactorBuilding)

|

(RPV Pedestal Seismic Response Analysis Model) |

Figure 3. Elastic-Plastic Analysis of RPV Foundation |

|

| |

|

| (3) |

Developing Methods for Evaluating Seismic Resistance of Piping |

| |

In view of the recent information about the elastoplastic behaviors of components, the examination of the allowable stress and others on piping was continued. The Proposed Post-Quake Seismic Integrity Evaluation Method (new evaluation method proposed) replacing the JEAG IIIAS, which was originally intended for design purposes, was examined to estimate its streamlining effects. As a result, it was found that an improvement equivalent to 1.2 times the current allowable stress could be expected.

The way the design damping coefficient was specified was reviewed. Issues were reviewed to allow for streamline evaluation based on, not design, but existing information about pipe supports and incidental materials.

|

| |

|

| (4) |

Evaluation and Examination Concerning Fatigue Strength |

| |

To evaluate the impact of strains caused by seismic load on material strength and fatigue life, five types of steel (SUS304TP, STP480, STPT410, SFVC2B, and SS400) as main pipe materials, in addition to the three types of steel evaluated the previous year, were evaluated in FY2008 for data enhancement. Figure 4 shows the fatigue test on pre-strained material and the impact of repeated pre-straining on the fatigue life of ferrite steel. The impact of repeated pre-straining on the mechanical quality and fatigue life of both ferrite steel and austenite stainless steel was insignificant. It was found that sufficient life margins against the design fatigue curves could be ensured for both steel types. Thus, it was confirmed that the alternate load resulting from the Chuetsu-oki Earthquake did not affect material strength and that the fatigue life of components can be assessed with sufficient margins by cumulative fatigue coefficient evaluation based on the design fatigue lines.

|

| |

|

|

| |

|

| (5) |

Preliminary Evaluation of “Safety Margins” |

| |

As a result of case studies into the conservativeness of seismic design analysis and evaluation using various piping system analysis methods, it was confirmed that significant margins were inherent in seismic design. Measures to better explain information about “safety margins” for the general public were also examined. |

| |

| 3. |

Action Plan for FY2009 |

In FY2009, experts will continue active discussions to expand the results of integrity evaluation of Kashiwazaki-Kariwa Units 6 and 7 to other units. The seismic safety evaluation of each unit will be continued, and performed on a full-scale basis following the decision on the design-basis seismic motion. As described below, the achievements made to date will be put together for active information transmission to relevant sectors.

|

| ・ |

Reasonable information will be put together by incorporating domestic and overseas engineering information, and information about seismic safety margins and others will be better explained. Efforts will be made to enhance coordination with the academic societies concerned and information transmission. |

| ・ |

Separate engineering achievements put together by each WG of the Committee, including the results of test, inspection and seismic evaluation of piping, and analysis and evaluation of reactor foundations, will be organized into a generalized engineering guideline for the convenience of the parties concerned |

| ・ |

A new WG will be set up by requesting the participation of electric power companies to develop a guideline that specifies the actions—including the tests and inspections that should be performed after an earthquake—taken for a restart depending on the magnitude of the seismic motion based on Safety Reports and others under review by IAEA. |

| |

|

| |

END |