|

|

|

Post-quake status of the Kashiwazaki-Kariwa Nuclear Power Station (Report #17)

- Activities of JANTI's SANE Committee - |

July 24, 2008

Rev.0

Japan Nuclear Technology Institute |

|

Japan Nuclear Technology Institute (JANTI) established the ”Structural Integrity Assessment Committee for Nuclear Components damaged by Earthquake (SANE)" (chaired by Toshiharu Nomoto, Professor Emeritus of the University of Tokyo) in September last year to examine and assess how important equipment at nuclear power stations can maintain its integrity in an earthquake that exceeds the design-basis level.The Committee has since carried out deliberations and released its interim report (outlines, Language: Japanese) in June.Many of the findings identified in the report have been reflected to inspections and evaluation activities by Tokyo Electric Power Company.The Committee's main achievements are as outlined below: |

Outlines of Main Achievements |

| (1) |

Proposing the basic policy of integrity assessment that combines facility inspections and seismic response analysis |

| ・ |

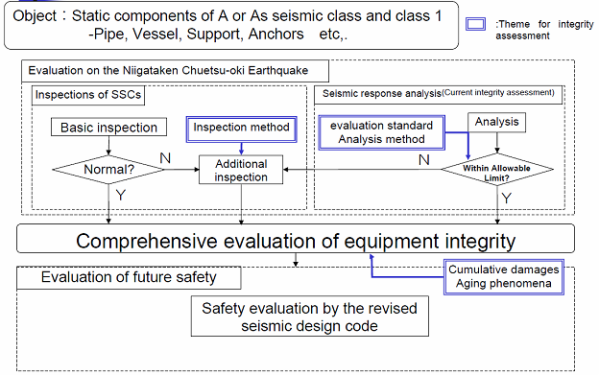

The Committee has summarized assessment methods for examining the "current integrity" in relation to the Chuetsu-oki Earthquake, and evaluating "future safety" concerning the facilities' continued use. |

| ・ |

The Committee has proposed a facility inspection method that combines "basic inspections" (e.g. visual checks) and "additional inspections" (e.g. non-destructive tests). |

| (2) |

Confirming the "current integrity" of Unit 7 at the Kashiwazaki-Kariwa Nuclear Power Station |

| ・ |

Based on the above, the Committee has used findings from past inspections and the results of analysis on various aspects including main parts' primary stress, typical components' fatigue, and stress on typical foundation bolts, and confirmed that main components inside plant buildings did not suffer damage that would affect their integrity. |

| (3) |

Study on inspection / assessment methods for each mode of damage |

| ・ |

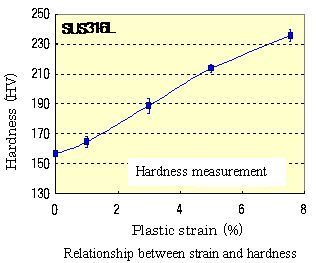

In assessing components that may have suffered localized plastic deformation in the earthquake, the Committee investigated methods for measuring plastic deformation, and recommended the Hardness Method to be applied on the site. |

| ・ |

The Committee has verified that the fatigue life of materials that have suffered plastic strain can be assessed by calculating the Usage Factor (UF) using the current Design Fatigue Diagram. |

| ・ |

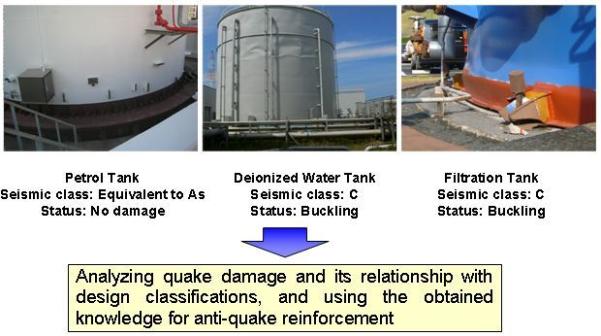

The Committee has assessed the damage types of components such as "filtered water tanks (Seismic Safety Design Class C)", which buckled in the earthquake. |

|

|

|

This report outlines the Committee's activities.

|

| |

|

| 1. |

Outlines of FY 2007 activities |

The Committee was formed in September 2007 with approx. 60 members, including 18 experts from universities and academic societies as full members and permanent participants representing electric power companies and manufacturers.The Committee met at the pace of around once a month to conduct a total of 6 meetings by the end of FY2007, engaging in active debate among experts from various fields.Six working groups (WG) were set up under the Committee, convening more frequent meetings for a total of 16 sessions.All members visited the Kashiwazaki-Kariwa Nuclear Power Station to confirm the extent of damage suffered by key components.

The integrity assessment of nuclear reactor components was extensively examined, including methods for assessing the integrity of components that came under seismic load, evaluation of judging criteria, and the use of analysis and tests for evaluating the damage of equipment.

Judging criteria were examined based on the Technical Guidelines for Aseismic Design of Nuclear Power Plants (JEAG 4601, Japan Electric Association), and with reference to U.S. standards and research findings including existing knowledge.As for the integrity of materials that suffered seismic load, the Committee conducted a fatigue test to reinforce data, and estimate fatigue strength.

|

| |

|

Table 1:List of Working Groups established under the Committee

| WG Name |

Main items examined by the WG |

| Evaluation Standard WG |

Methods and standards for assessing structural integrity |

| Inspection WG |

Methods for examining equipment's plastic strain |

| Fatigue / Material Test WG |

Evaluation on the fatigue strength of materials exposed to earthquakes |

| Dynamic Estimation WG |

Methods for evaluating equipment integrity under dynamic load |

| Anchor Bolt & Nut WG |

Methods for evaluating the integrity of bolts and other joining materials |

| Aging WG |

Plant aging that should be assessed in combination with the effect of earthquakes |

|

| |

|

| 2. |

Achievements in FY2007 |

| (1) |

Proposing the basic policy of integrity assessment that combines facility inspections and seismic response analysis. |

| |

The Committee defined the components, piping and support structures that made up reactor pressure boundaries as the equipment subject to evaluation, drew up the integrity evaluation flow-chart consisting of inspections and analysis, and examined issues required for integrity evaluation, including inspection methods and evaluation methods.

The Committee employed the perspectives of "component evaluation against past earthquakes" (i.e. evaluating equipment that became subject to seismic load, according to the results of seismic response analysis) and "component evaluation against possible future earthquakes" (to determine integrity for continued use) in compiling approaches for setting evaluation standards to examine "current integrity" and "future safety".

|

| |

|

|

| |

|

| |

The allowable stress status IIIAS, as defined in the Technical Guidelines for Aseismic Design of Nuclear Power Plants (JEAG 4601, Japan Electric Association), was applied to each of the evaluation standards.This defines the status in which equipment / structure is free from overall plastic deformation (although allowing localized plastic deformation).Even if this standard is exceeded, up-to-date specifications in or outside Japan may be applied if they are appropriate.

As for the continued use of equipment exposed to seismic load, the Committee decided to examine each case based on the evaluation results on the "current integrity" and "safety against possible future earthquakes".

It was also agreed to take an approach that reflects real situations when examining the actual integrity of reactor components that experienced the Chuetsu-oki Earthquake.In other words, "design-basis evaluation (evaluation encompassing margin against design-basis earthquakes)" was replaced with "evaluation based on actually experienced seismic load" to carry out comprehensive assessment that combines seismic response analysis and the results of visual checks and other inspections.

|

| |

|

| (2) |

Confirming the "current integrity" of Unit 7 at the Kashiwazaki-Kariwa Nuclear Power Station |

| |

The seismic response analysis of Unit 7 included assessing primary stress, evaluating fatigue, conducting analyzing the timing of control rod insertion, and evaluating the stress generated at the foundation bolts for the reactor core isolation cooling pumps (RCIC pumps).The results confirmed that the Chuetsu-oki Earthquake did not cause damage that would affect components.Material tests also confirmed that the fatigue life of plant equipment has sufficient margin, even after considering the impact of the Chuetsu-oki Earthquake. |

| |

|

| (3) |

Study on inspection / assessment methods for each mode of damage |

| |

1. Assessing the materials that may have suffered plastic deformation in the earthquake

Prior to evaluation, the Committee identified (1) ductile fracture, (2) plastic collapse, (3) excessive deformation (e.g. ratchet deformation), (4) buckling and (5) fatigue as key earthquake-induced events that should be considered, and pointed to the need to study inspection / assessment methods for each mode of damage.

Of the aforementioned damage types (1) to (5), (1) to (4) involve significant deformation, and may be detected through a visual check.The Committee therefore set the criteria for determining skill levels of personnel conducting inspections including visual checks, and summarized the basic approach to facility inspections.Additional inspections were also recommended, together with analytical assessment, to determine the presence of minor plastic deformations that could not be easily detected through visual checks.

Of the aforementioned damage types (1) to (5), (1) to (4) involve significant deformation, and may be detected through a visual check.The Committee therefore set the criteria for determining skill levels of personnel conducting inspections including visual checks, and summarized the basic approach to facility inspections.Additional inspections were also recommended, together with analytical assessment, to determine the presence of minor plastic deformations that could not be easily detected through visual checks.

More specifically, the Committee examined currently-available methods for measuring plastic deformations, namely (1) hardness method, (2) magnetostriction method, (3) sonic velocity method, (4) Barkhausen noise method, (5) replica observation method and (6) ECT.Comprehensive assessment on on-site applicability and other aspects concluded that the "hardness method" was the most superior method for identifying plastic deformations.

The Committee also provided insight into the methods for inspection / assessing foundation bolts for a reactor pressure vessel, transformers, etc.Recommended methods have been adopted in additional inspections.The results of such inspections are being evaluated for their validity.

|

| |

|

| |

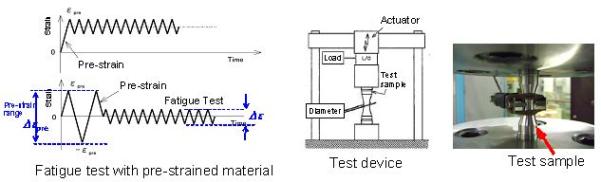

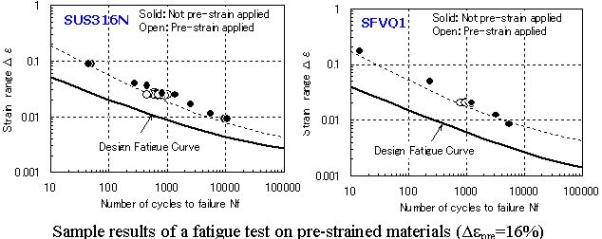

2. Testing materials that simulate plastic deformation induced by seismic load

When a component with no visible deformation is found to have small plastic deformations, the impact of fatigue must be considered.When exposed to a severe load from an earthquake, etc., a material generally hardens, with the level of high-cycle fatigue strength increasing.However, the level of low-cycle fatigue strength may decrease due to the effect of the excessive load.For this reason, the Committee examined the low-cycle fatigue strength of pre-strained materials, applied with load that simulates plastic deformation caused by seismic load.

|

| |

|

|

| |

|

| |

The results showed that typical materials such as stainless steel and low alloy steel, pre-strained at approx. 8%, had substantial margin in fatigue strength against the current Design Fatigue Curve, pointing to minimal effects from pre-strain. |

| |

|

|

| |

|

| |

Based on the test results, low-cycle fatigue may be assessed with the existing method even with the presence of pre-strain of approx. 8%.This means that the "hardness method", which has the strain detection precision on the order of several %, can generally determine the presence of significant strains that could affect the plant.

Since components and piping contain processing strains from the construction stage in the process of bending and welding, the Committee recommended that hardness is measured and compared between locations with significant seismic impact and locations with minimal seismic impact, so as to identify the effect of an earthquake.

|

| |

|

| |

3. Evaluating the types of component damage suffered in the earthquake

Facilities that received different types of seismic safety design suffered a different extent of damage.Taking an analytical approach in assessing the damage can help identify the impact of earthquakes on components.For example, the Committee focused on the buckling of the base of a filtration tank (Class C), and conducted an investigation to not only prevent the recurrence of the event, but also to attain broader insight into technology for assessing structural strength.Three-dimensional dynamic analysis identified a mechanism of "elephant foot bulge" (a type of local buckling), in which the level of displacement increased suddenly immediately after maximum acceleration was applied.

Tanks that did not suffer buckling will be analyzed in the future to identify factors that cause damage to tanks in an earthquake, and formulate countermeasures.

|

| |

|

|

| |

|

| 3. |

Activities for FY2008 |

In FY2008, the Committee will continue to examine existing issues, and also commence full-scale efforts to evaluate future component safety based on the design-basis seismic motion, defined for the Kashiwazaki-Kariwa Nuclear Power Station.

More specifically, the Committee will continue to evaluate the plastic strain of piping and integrity of bolts and other joining materials, while addressing fresh tasks such as the applicability of analysis methods in view of the elastic and plastic behaviors of components / piping, rational vibration properties of piping, and seismic safetyof support structures for a reactor pressure vessel.Eight experts from the fields of architecture, civil engineering and dynamic vibrations have been invited (26 members in total) with the working groups realigned into (1) Evaluation Standard WG, (2) Inspection WG, (3) Fatigue / Material Test WG, (4) Piping Vibration Evaluation WG and (5) Building-Equipment Compounding WG.

The Committee will continue to facilitate frank debates among experts, reflect various achievements to the Kashiwazaki-Kariwa Nuclear Power Station's integrity assessment and future safety assessment as required, and provide technical support to the Power Station in its seismic reinforcement work and preparation for plant restart.At the same time, information will be distributed actively to relevant parties to promote mutual coordination.

|

| |

|

| |

END |

|

|

|

|