Post-quake

status of the

Kashiwazaki-Kariwa

Nuclear Power Station

(Report #11)

- Update on the status

of inspection and

restoration work through

to November 8

-

The Report #11

follows on from Report

#10 in summarizing the

post-quake status of the

Kashiwazaki-Kariwa

Nuclear Power Station

and giving the overview

of the initiatives,

trends and other details

involving Tokyo Electric

Power Company (TEPCO)

and other relevant

organizations.

1. Earthquake

response evaluation of

reactor

buildings

TEPCO briefed on the

earthquake response

evaluation of the power

station's reactor

buildings at the 6th

meeting of the

Structural Working Group

under the Anti-Quake

Structural Design

Subcommittee, Nuclear

Safety Committee, METI

Advisory Committee for

Natural Resources and

Energy, convened on

October 23.

This assessment used

seismic observation

records to simulate the

earthquake response of

the reactor buildings

for analysis, and

calculated their maximum

response shear strain

accordingly, to compare

the figure against the

benchmark figure for the

development of shear

cracks (Allowable Stress

Design, Architectural

Institute of Japan

Standards for Structural

Calculation of Steel

Reinforced Concrete

Structures and Brief

Commentary, 1999).

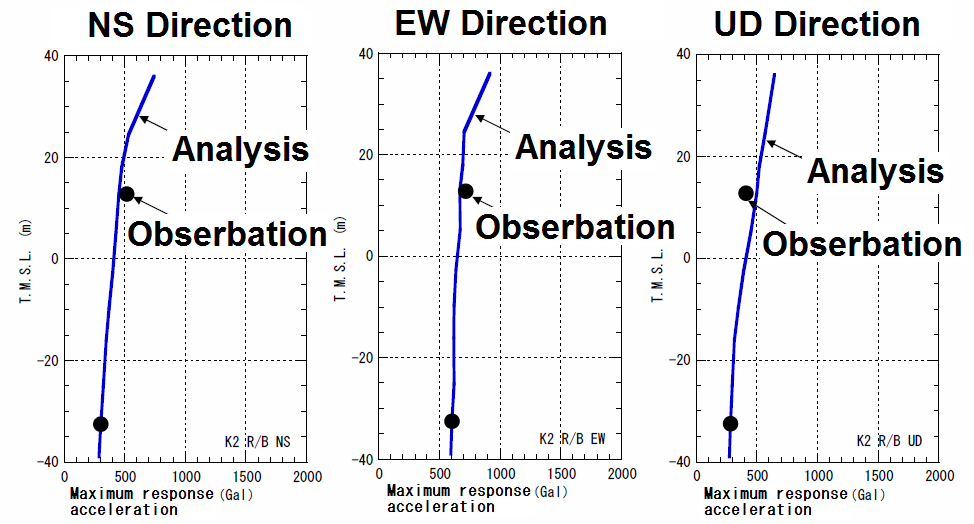

(1)

Simulation

reproducing the

earthquake response

of reactor

buildings

When the following

conditions are taken

into account, the

simulation of reactor

buildings' earthquake

response produced

results that match

the seismic

observation records

relatively well.

i.

Young's modulus

for concrete

ii. Wall

setting for

rigidity

evaluation (Wall

that meets the

criteria

stipulated in

Article 19 of the

AIJ Standards for

structural

Calculation of

Steel Reinforced

Concrete

Structures and

Brief Commentary

[Allowable

Stress

Design],

1999)

iii. Ground

foundation around

the reactor

buildings

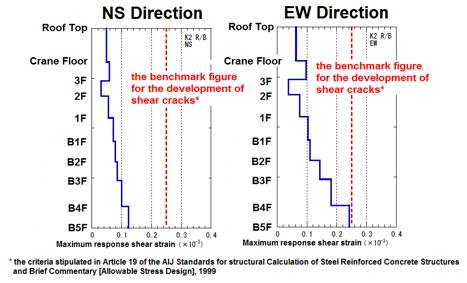

(2) Maximum

response shear strain

of the reactor

buildings

The conditions of

the simulation were

applied to calculate

the maximum response

shear strain of the

reactor buildings,

and the results for

all the reactor

buildings were below

the benchmark figure

for the development

of shear cracks,

indicating that the

structures fell

within the designed

scope of resilience.

WG members did not

present any major

arguments that deny

the finding.

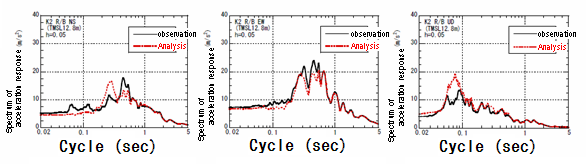

(3) Summary of

TEPCO's assessment

results and immediate

initiatives

i. The

analysis that took

actual earthquake

conditions into

account was able

to reproduce the

seismic

observation

records relatively

well. (Figures 1

and 2 show the

example of Unit 2,

which suffered

seismic motions

that exceeded the

level assumed at

the time of plant

designing most

drastically.)

ii. The maximum

response shear

strain, obtained

in the analysis,

indicates that the

reactor buildings

fall within the

designed scope of

resilience.

(Figure 3 shows

the example of

Unit 2.)

iii. The

results are to be

compared against

the outcome of

crack checks and

other inspections

currently underway

to confirm the

buildings'

integrity.

Fig. 1 Maximum response

Acceleration (Unit

2)

Source: Courtesy of the

TEPCO

Fig. 2 Comparison of

floor response spectrum

(on a mid floor) (Unit

2)

Source: Courtesy of the

TEPCO

Fig. 3 Maximum response

shear strain of the

reactor building (Unit

2)

Source: Courtesy of the

TEPCO

2.Status of main

inspection and

restoration work

Detailed inspection

and restoration work on

equipment, etc. is

systematically being

carried out at the

Kashiwazaki-Kariwa

Nuclear Power Station at

present. TEPCO releases

inspection findings as

they become available.

See

the attachment for a

list of performed and

planned inspection /

restoration work.

According to the

reference materials

released by TEPCO thus

far, no serious plant

damage has been

identified in the course

of the inspection /

restoration work. The

following describes the

results of some of the

inspections that have

caught the attention of

JANTI:

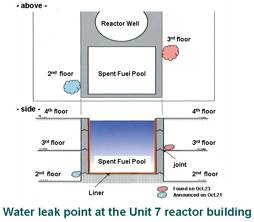

(1)-1

Water leakage at Unit

7

TEPCO completed

filling the Unit 7

reactor with water on

October 8, 2007.

Although some seepage

has subsequently been

identified as

described below, the

amount of water

involved is minute

with no radiation

effects to the

outside

environment.

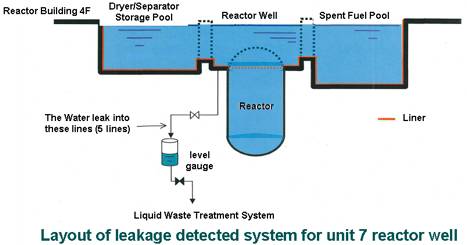

a.

Detection of drain

water from the

reactor well

liners

TEPCO found

some water inside

a level gauge

connected to the

well liner, and

conducted trend

monitoring as well

as analysis of the

water itself, to

detect a minute

amount of

radioactive

material (antimony

124).

It is believed

that some of the

water used for

filling the upper

reactor flowed

into the level

gauge via the

liner. (See the

diagram

below.)

Source: Courtesy of the

TEPCO

This

leakage did not

cause any

radioactive impact

on the external

environment.

The liner is

currently being

inspected, with

minor damage that

could lead to

leakage identified

in two locations.

The damaged

sections are to be

temporarily

repaired before an

in-core inspection

is conducted.

b. Water

leakage in

radiologically

controlled areas

on the 2nd floor

of the reactor

building

TEPCO

identified water

seepage from minor

wall cracks and

puddles of water

on the floor in

radiologically

controlled areas

on the 2nd floor

of the reactor

building. Analysis

of the leaked

water detected a

minute amount of

radioactive

materials

(cobalt-60 and

cesium-137).

The amount of

water leaked

totaled 6.5 liters

containing

radioactivity of

250Bq, which is

equivalent to

radioactivity

found in around

30cc of radon spa

water.

The leakage

stayed within the

radiologically

controlled area,

thereby posing no

radiation impact

on the external

environment.

Since the

amount of leakage

drops when the

water level of the

reactor well goes

down, TEPCO

suspects that the

leakage came from

the well. An

investigation on

the well will be

conducted in the

future (See

the attachment

for a schedule of

Well Inspection of

Unit 7) to

identify the

location of the

leakage. (See the

diagrams on the

below.)

c. Water

seepage at a

concrete joint on

the north side of

the reactor

building's 3rd

floor

TEPCO also

identified minute

water seepage at a

concrete joint on

the north side of

the reactor

building's 3rd

floor. Analysis of

the water detected

a minute amount of

radioactive

material

(cobalt-60). The

amount of water

leaked totaled

200cc containing

radioactivity of

0.8Bq, which is

equivalent to

radioactivity

found in around

0.1cc of radon spa

water. (See the

diagram shown

below.)

The leakage was

contained within

the radiologically

controlled area,

thereby posing no

radiation impact

on the external

environment.

Source: Courtesy of the

TEPCO

(1)-2

Status of large tanks

containing

radioactive materials

such as spent fuel

pools

As part of the

investigation into

drain water from the

reactor well liners

at Unit 7, TEPCO have

checked the status of

large tanks

containing

radioactive

materials, such as

spent fuel pools, at

all Units. (See

the attachment

for a list of

confirmed statuses

[Source: TEPCO

press release]).

As of now, the

investigation has

found no significant

water leakage

suggesting leakage

from a reactor well

liner in Units other

than Unit 7.

At Unit 1, minor

water seepage,

suspected to be

attributable to

sloshing and

resulting

infiltration of

overflowed water

(See

Report #4), was

found on the concrete

wall of the spent

fuel pool at the

lower part of the

reactor operating

floor. A minute

amount of radioactive

material was detected

in the water, and

TEPCO plans to

continue monitoring

the site. (See the

diagram on the below.

Source: Courtesy of

the TEPCO)

(2)

Control rod removal

trouble at Unit 7

After the removal

of fuel assemblies

that started on

October 11, Unit 7

was having its

control rods pulled

out and encountered

trouble in doing so

with one of the

control rods.

This did not cause

safety issues because

all the adjacent fuel

assemblies had

already been removed,

and also because the

control rod was held

in a stable state

with support

fittings.

The applicable

control rod has since

been pulled out

according to the

procedure pre-defined

for anticipated

problems**. In the

overhaul of the

control rod drive

unit, conducted over

seven days from

November 3, detailed

inspections and

assessment were

carried out on the

labyrinth seal and

latch mechanism, but

did not find any

attributable

cause.

While the

investigation is

still in progress,

since another scram

attempt successfully

removed the control

rod, it is suspected

that a temporary

increase of

frictional resistance

in the CRD played a

part. Although the

investigation

indicates that the

event was a temporary

issue, TEPCO plans to

inspect reactor-side

equipment (control

rods, fuel support,

fuel guide) to be

safe.

The

inspection

schedule is as

shown in the

attachment (Source:

TEPCO press

release).

**Pre-defined

procedure

The applicable

control rod is

designed to

use"electrical

drive" to conduct

regular insertion

/ removal but use

"hydraulic

pressure" for

emergency

insertion (scram).

A recovery

procedure is

pre-defined to

address any

failure that can

be anticipated

because of the CRD

structure.

In this case,

the applicable

control rod

received regular

removal operation

(electrical

drive), before the

CRD was applied

with the hydraulic

pressure similar

to that used in a

scram to conduct

full control-rod

insertion, and

then a normal

removal operation

again.

(3) Status of

turbine internal

inspections

At all the plants,

all turbine casings

are to be opened for

detailed inspection

according to

the

schedule shown in the

attachment

(Source: TEPCO press

release).

A turbine internal

inspection was

conducted from

October 11 to October

25 at Unit 6, which

was in the shutdown

state at the time of

the earthquake. This

was the first turbine

internal inspection

conducted.

<Contact marks

on the Unit 6

turbine>

Although the

inspection found

contact marks at

several locations,

they were all minor,

and will be restored

through applying

maintenance work or

replacing parts. More

specifically:

- Minor

contact marks,

only recognizable

as contact sheen,

were found on the

moving and static

blades of both

high-pressure and

low-pressure

turbines. These

marks do not

affect the

turbines'

functionality, but

are to be put to a

non-destructive

test in a detailed

inspection in the

future.

- Cracks were

found on the oil

seal ring of the

main

turbineÅfs

thrust bearing.

The part will be

replaced.

- Contact marks

were also present

on bearing metal,

gland gaskets, oil

slingers and

diaphragm nozzle

gaskets, but they

were all minor and

do not affect

their

functionality. The

parts will be

either given

maintenance work

or replaced.

(4) Gradient

changes at power

station buildings

(interim

report)

The changes of

building gradient

have been identified

as shown below,

indicating no

significant tilting

that could deal a

structural impact on

the buildings. The

extent of tilting is

well under the

subsidence limit

(0.5~1.0 x

10-3rad(1/2,000~1/1,000):

"Benchmark of the

subsidence limit

under constant load",

Recommendations for

Design of Building

Foundations, revised

in 2001

[Architectural

Institute of

Japan]).

However, since

this earthquake

struck geodetic

control stations

designated by the

Geographical Survey

Institute, the

reactor buildings are

tentatively defined

as the fixed points,

making it impossible

to determine the

absolute extent of

land movements at

this stage. This land

survey was rated

Level 4, and has the

allowable margin of

6mm against 100m.

|

Unit

|

Building

name

|

Maximum

gradient

change

from (2)

pre-earthquake

to (1)

post-earthquake

|

Maximum

gradient

change

from (3)

initial

survey

to (1)

post-earthquake

|

|

Gradient

|

Gradient

|

|

1

|

Reactor

building

|

Approx.

1/19,000

|

1/14,000

|

|

Turbine

building

|

1/29,000

|

1/8,300

|

|

2

|

Reactor

building

|

1/9,700

|

1/8,700

|

|

Turbine

building

|

1/11,000

|

1/8,300

|

|

3

|

Reactor

building

|

1/32,000

|

1/13,000

|

|

Turbine

building

|

1/14,000

|

1/27,000

|

|

4

|

Reactor

building

|

1/20,000

|

1/27,000

|

|

Turbine

building

|

1/7,400

|

1/7,000

|

|

5

|

Reactor

building

|

1/12,000

|

1/9,200

|

|

Turbine

building

|

1/12,000

|

1/11,000

|

|

6

|

Reactor

building

|

1/7,300

|

1/6,400

|

|

Turbine

building

|

1/14,000

|

1/14,000

|

|

Control

building

|

1/6,400

|

1/5,600

|

|

Waste

processing

building

|

1/12,000

|

1/7,800

|

|

7

|

Reactor

building

|

1/4,700

|

1/6,100

|

|

Turbine

building

|

1/8,400

|

1/7,800

|

(Source: Courtesy of

the Tokyo Electric Power

Company, Inc.)

END

|